Directional bore drilling represents revolutionizing the way we approach subsurface construction, offering creative solutions for multiple industries. By allowing drillers to maneuver beneath the Earth's surface with exactness, directional drilling reduces surface disruption and opens up new avenues for infrastructure development. Regardless of whether it is for oil and gas extraction, utility installation, or renewable energy projects, this technique has transformed traditional drilling practices.

As we delve deeper into the world of directional drilling, we'll examine its evolution, key technologies, and the wide-ranging applications that make it an essential tool for modern construction. From understanding the differences between vertical and horizontal drilling to analyzing the benefits such as time and cost savings, this guide serves as a comprehensive resource for those looking to understand the fundamentals and advancements in this state-of-the-art field.

Grasping Directional and Horizontal Techniques

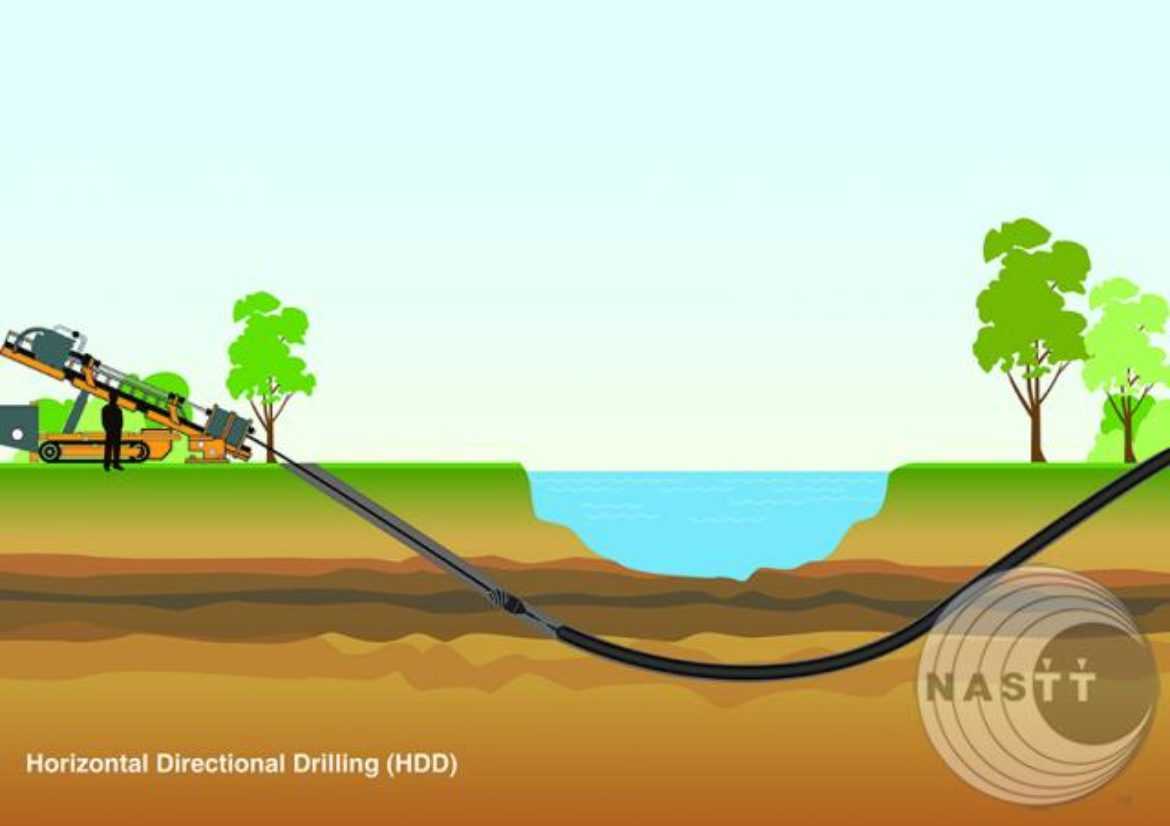

This technique is a technique that allows drillers to produce boreholes that deviate from a straight up-and-down path. This method is vital for reaching resources that are not immediately beneath the drilling site or for installing pipelines in urban areas where capacity is restricted. Unlike traditional vertical drilling, which only gives access to the formation immediately below, directional drilling offers the flexibility to target multiple drilling targets from a unified location, greatly boosting efficiency.

The method of directional drilling involves a variety of technologies and equipment. Drill bits, mud motors, and custom tooling are key components that enable the drill to move both lateral and at multiple angles. Advanced bore tracking and monitoring systems provide accurate navigation, enabling operators to maintain precise control over the drill path. This ability is vital in environments where barriers may be found, such as urban development or ecologically sensitive locations.

Grasping the distinctions between vertical and horizontal drilling is crucial for anyone exploring this domain. Vertical drilling provides ease and clarity but is often limited in application. In comparison, horizontal drilling can access more resources and is increasingly utilized across different industries. This adaptability not only facilitates efficient resource extraction but also reduces the environmental impact, making directional drilling a favored choice in modern engineering projects.

Benefits of Inclined Drilling

Horizontal drilling offers considerable advantages over traditional drilling methods, especially in terms of effectiveness and cost savings. By enabling operators to drill at multiple angles, this technology reduces the need for various drilling sites. This not only reduces the overall duration spent on a project but also lowers the financial investment required. The ability to access various targets with a single setup translates to significant savings for companies, making inclined drilling a preferred choice for many projects.

Additionally, another significant benefit is the limited surface disruption connected to inclined drilling. In urban areas or sensitive environments, the ability to maneuver around obstacles without extensive excavation is invaluable. This technique facilitates the installation of utilities, pipelines, and other facilities without the extensive land disturbance traditional methods often entail. As a result, companies can maintain operational efficiency while also meeting environmental and regulatory standards.

Moreover, inclined drilling is known for its enhanced precision when compared to standard drilling approaches. Advances in technology, such as real-time bore tracking and monitoring systems, enhance accuracy during drilling operations. This heightened precision not only leads to better resource extraction but also ensures safer drilling practices. As a result, the risk of environmental impact is significantly reduced, making directional drilling an essential method in the current construction and energy sectors.

Emerging Trends in Drilling Direction

As the industry continues to evolve, one of the most significant trends in directional drilling is the adoption of AI and automation. These tools are set to enhance precision and effectiveness, allowing operators to make real-time adjustments based on analytics. By harnessing AI, companies can optimize drilling trajectories and minimize threats associated with human error, leading to more positive results in difficult conditions.

Another noteworthy development is the rising use of state-of-the-art sensor systems and applications in directional drilling operations. These technologies facilitate better bore tracking and monitoring solutions, providing live feedback on the performance of drilling. Directional Drilling Dublin Ireland enhances operational efficiency but also supports safer operational practices by allowing drilling specialists to respond quickly to unexpected changes in geological conditions.

Finally, the trend towards eco-friendly infrastructure is shaping the future of directional drilling. Organizations are exploring eco-friendly drilling solutions and procedures that reduce environmental impact. As urban areas continue to expand, the demand for minimally invasive drilling approaches will grow, emphasizing the need for innovations that align with sustainability goals while maintaining cost efficiency and efficiency in utility installations and pipeline installations.